Towards the end of last week, in the tube on the way home after work, I was scanning the front page of the guardian, looking for the day’s news when an article about the Volksbühne caught my eye, and because I am a sucker for news of Berlin from overseas, especially of the non-political kind, I opened the article and started to read it, and imagine my surprise when, about halfway through the article, I saw pictures of a massive prop whose components I had cut not two months earlier.

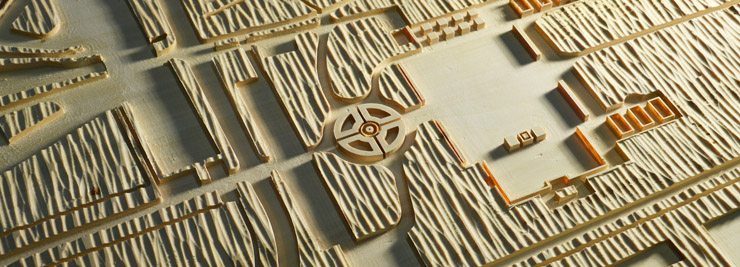

Its not every day I get to see pictures of work I do in the Manchester Guardian. What was interesting was that while I was cutting the pieces out I had no idea what they would be used to build, but when I saw all of the dozens and dozens of circles I had cut out in the picture below, I recognized them instantly. They had been used as the ribs for the framework of a massive pipe that rolls around the stage on a current Volksbühne production that is called “pfusch”.

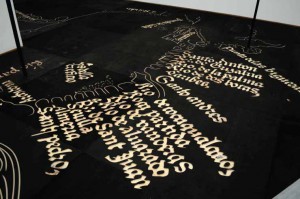

The guardians piece is well worth reading. It tells about the Volksbühne (old, and socialist), and about their stage production workshop (big), and about how the the Volksbühne is trying to adapt to modern times by recruiting a big name Theater Manager.

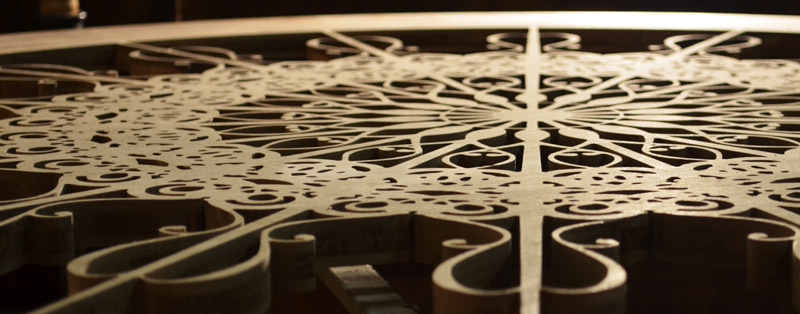

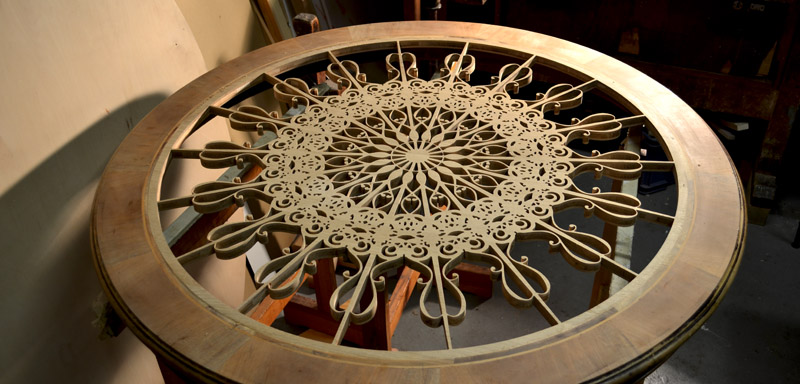

We have cut parts for stage production projects for the Grips Theater as well as for the Volksbühne. Cnc routing lends itself well to this kind of thing, because no matter how big a workshop, a cnc router is just more efficient when it comes to cutting organic forms.