This is where you will find information about our pricing, what kind of material we cut, and what we need from you in order for us to get cutting, – and a bit about our machine right at the end.

The minimum order value that we accept is 79,-€ If you want to know what a job will cost, please send us a mail – only written offers are binding. Customarily the time needed for setting up a job will be billed. If you don’t have a Vector file for the job, then making a cost estimate becomes far more difficult: for this reason it is in your interest to provide accurate vector files. It is best if you send us a vector file with measurements, and the type and thickness of material that we should cut. Job requests without name, address, and above all vector files, cannot be processed. Information about the file formats that we require can be found here.

Materials

We can cut a large range of materials, and have direct access to the Modulor catalog. We also cut your own material, depending on what it is.

Wood

Plastics

Non-ferrous metals

What we need

In order to cut out your project, we need a vector based file, saved in one of the following formats:

If you can’t save your file in one of these formats, inform yourself online how to convert them. (We use zamzar)

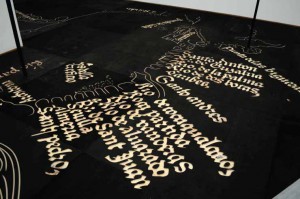

Our CNC Router

Our 3-axis CNC router* has a table size of 2500 x 1450, and a cutting area of 1850 x 1250 x 30 mm. We can cut nearly any non-ferrous material, including hardwoods, plywoods, MDF boards, sandwich panels, aluminium, brass, acrylic, Corian and all densities of modeling foams.

Our machine was built two years ago by Axel Stab, who occasionally posts photos and videos related to cnc technology.

* A 3-axis router is a machine used to rout out (hollow out) an area in the face of a piece of material (wood, plastic, metal, etc.). A cylindrical metal cutter similar to a drill bit is moved on three axis (left, right, forward, backward, up and down) and remove the material placed on the table underneath.

** It is possible to cut a thicker piece of material (up to 80mm) if the length/width are not too large (and the piece itself not too heavy). In case the thickness is too important to be achieve in one go, it is possible to separate the design in different layers, and assemble them on top of each other after routing.