In the first post Jeffery explained the difference between 3d printing and cnc routing.

In this post I’d like to explore why there are so many online 3d printing and lasercutting services, where you can upload a file, and receive the object within a matter of days by mail, and why this kind of service is not being used for cnc routing.

Ponoko has pioneered online lasercutting since 2007. Their service is transparent in an exemplary way; you upload a file, choose the material you want cut, and ponoko will show you the price in realtime. No need to send a request, and then wait for a quote. Shapeways offers 3d printing in very much the same way.But, apart from emachineshop.com there is no cnc routering company out there with that kind of service, which is strange, because cnc routering has been around much longer than either lasercutting or 3d printing.

Ponoko used to offer cnc routering, but that didn’t last long (it was launched in 2011, and came to a halt in on the 18th of Feb 2013). I’m not sure why ponoko stopped offering cnc routing, but my guess is that its just a lot more complicated than lasercutting or, for that matter 3d printing. I know, from my own experience, with the kind of requests I get, that its just really really hard to estimate machine time accurately in a consistant way, which is what is necesary if you want an algorithm working out the quotes instead of a human.

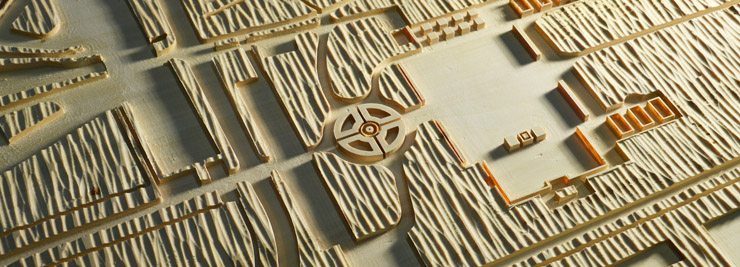

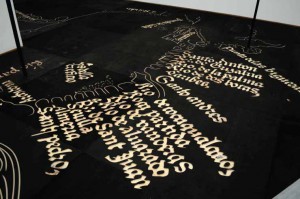

This weakness of cnc routing is also its strength. Although its more complicated to use, and hard to calculate cost, the results are mostly much much better. I could never have produced anything like the lime wood model shown in the picture at the top of this post or the walnut box below using 3d printing or lasercutting, and that will not change until a 3d printer is invented that can print wood, and that will not happen in my life time.

3d printing is becoming possible in materials other than plastic such as metal and ceramic, in fact, there is even a material that contains wood fibers, (it looks and feels like a cross between mdf and plastic) but if you want to cut something out of walnut or oak, then cnc routing is by far the best method. Laser can cut almost any material, but some materials emit dangerously poisonous gases when lasered, and cutting with light is never a straight, 90 degree, cut because the laser focusses on the top of the material. This is not really an issue with thin materials, but on everything over 10mm it becomes more and more noticable. This is why the New Yorker profile on Mr Ive mentioned 3 cnc machines behind a glass wall in his design studio at apple. If you want to make state of the art design, then the machine of choice is a router.

So because the types of materials, and the material thickness (in the case of lasercutting) are limited, it means that calculating cost realiably is easier.

I like your website. I have been building and operating CNC routers for 20 years. I developed automated pricing for 5 axis monolithic machining based on toolpath strategies but we dont offer it online. Im going to pass the shop for a visit today as I’m in Berlin.

Regards

Ben