It used to be that CAD software and other 3d design solutions were complicated and difficult to use without years of training. Today, however, the traditional forms of software are becoming easier to use and there are alternatives such as Google sketchup which allows users to intuitively design 3d models for free. The creation of physical objects from those models is also within the grasp of the average user today, thanks to 3d printing and other types of automated manufacturing.

3d printing is a process by which objects are created automatically by a machine which drops bits of material layer-by-layer. The material is forced through an aperture which is controlled much like the ink jet of a printer. This is called an additive manufacturing method, since the material is added rather than removed. Theoretically, any shape can be produced with this method; it makes no difference if the object contains tight corners, hollow areas, or complex structures, since the object is built from the ground up. The main disadvantage of 3d printing, however, is that the choice of material is extremely limited. The material must be a type that can easily be transformed into a liquid, applied, and quickly solidified once again. For most prototyping applications, this is certainly sufficient, but for many applications, such as the fabrication of tools or parts, 3d printing often cannot produce a part with the desired material properties.

Subtractive manufacturing, on the other hand, starts with a block of material and removes everything but the desired object. This has some important advantages over 3d printing, in that most limitations on what type of material can be used do not apply. Even high carbon steel can be cut away using the right tools. The most ubiquitous subtractive manufacturing technology is the CNC router. The CNC router is a router spindle that is mounted over a table and controlled automatically. Sometimes the spindle itself can even be rotated on its axis to produce very complex objects. The most complex controller cannot produce some types of objects, however, since hollow areas are impossible, and inside cuts can only be as precise as the size of the tool permits.

Other types of subtractive manufacturing include laser cutters and plasma torches which can cut even the most resilient of materials.

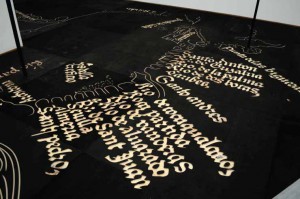

Subtractive manufacturing like CNC routers are perfect for the production of flat objects or ones that require a specific material be used. Applications like inlaying or engraving, or the production of lettering, signs or logos are perfect for CNC routing since very little material need be removed. Printing these types of objects would be slow and expensive, and in many cases, CNC routing allows very cheap materials to be used, like MDF or plywood. Prototypes or furniture which require structural soundness are also perfect applications, since the materials used can be selected based on their cost and strength, rather than the ease at which they can be liquefied.

3d printing is by no means the only type of additive manufacturing. With the use of lasers and chemical processes, fluids can be solidified by means other than simply melting plastics. Some techniques, like stereolithography, can transform the top layer of fluid in a vat into a solid. Slowly the part is lowered into the vat, and the next layer is produced. Laser sintering is a system which helps bypass some of the limitations of 3d printing by using a laser to melt small tiny pebbles of material in place. This allows for a greater range of materials to be used.

If this discussion seems too academic, remember that 3d designs and design software are becoming ever more accessible to the average user. Google’s 3d Warehouse, for instance, allows users to share 3d designs which can be modified and produced by anyone with access to an automated manufacturing device. Also, with the advent of 3d scanners and applications like 123D Catch, which can piece individual photos together into a coherent 3d model, reproducing and/or modifying an object is a breeze. Never before has so much power been the in the hands of individuals to design and build complex and precise objects.

Leave a Reply