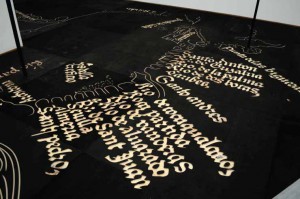

My first big job, routing a huge wooden map of Mexico City, came when I still had a very small workspace across the street in betahaus. It was a regular day, I was just sitting around with not too much to do, and then Mariana Castillo Deball knocked on the door, and asked me if I had time to do a project for her. This was a case of pure good luck, because Mariana lives right in the neighborhood, and because she had noticed my workshop, and that I had a CNC router. Most of the work I do, 85 to 95 percent, comes to me online, but there have been some important exceptions. The job that I would do for her for the Hamburger Bahnhof brought in more than a quarter of my earnings for that year, and because it was my first year, it literally saved my ass, financially speaking. [Read more…]