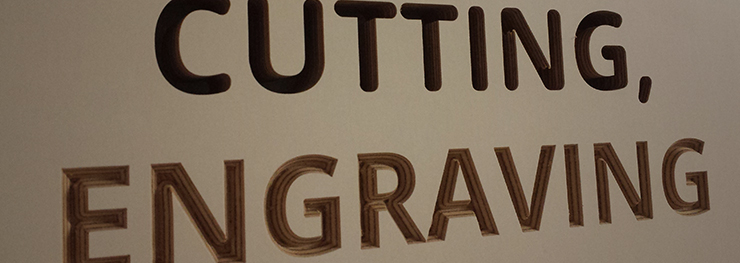

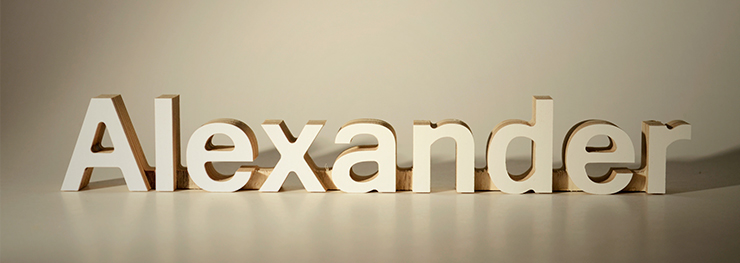

When starting a project for a CNC router, the design may seem daunting at first. It is not obvious that most CNC projects are simple in their design. It often isn’t necessary, for instance, to have a 3D model of the project. This is because many of the operations a CNC router performs need only two dimensional paths. Take 3D lettering or engraving as an example. Although the object is three-dimensional, the paths required to make it are simple and only two dimensional.

This means that the router spindle need only be told how to move in the x and y axis, and the moves in the z axis are done automatically to the necessary depth. Some technologies are fundamentally 2d. Laser and plasma cutters, for instance, cut all the way through the material and don’t have the ability to create pockets or low points.

2.5D – Simplification of 3D CNC Objects

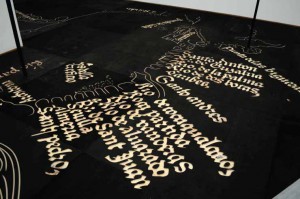

Some routers (usually older models) also lack the ability to simultaneously move the spindle up and down on the z axis while moving on the x or y axes. This means that a piece can have different points of different depths, but that the step must be done all at once. Thus, it is impossible to create a smooth face at any angle other than parallel or perpendicular to the tool. An object milled in this way is referred to 2.5D, since it was produced using only 2D tool paths and depths for each area to be milled. Another type of 2.5 cutting is the V-carve. This is a process by which a V shape is engraved, creating a 3D profile in the object.

The smooth face must be produced by a CNC routing setup that is capable of moving gradually on the z-axis while moving on the other axes. This means that the router and the tool paths are 3D, but it is nevertheless called a 2.5D process, since only 2D information must be fed into the software, along with the desired depth or width and angle.

The following summary could be helpful for anyone wanting to do a project with a CNC router. This table can tell you what kind of information you need to do each kind of project:

| Project type: | 2D-3D | Information Required for Design |

| Simple shapes, lettering | 2D | 2D toolpaths (vector file) |

| Simple engraving/facing | 2.5D | 2D toolpaths (vector file), depths of faces |

| V-Carve engraving | 2.5D | 2D toolpaths (vector file), angle of cuts and depth or width |

| 3D models | 3D | 3D CAD file |

For more information on what kind of files we can read at formcut, click here.

If it still seems complicated, or if you have a simple 3D plan, but no way of creating a mockup, send us an e-mail or give us a call. We can provide 3D consulting, or if the project is simple enough, maybe we can make it using only 2D methods.

Leave a Reply